Why You Need Spare Part Catalouge For Merlo?

Why You Need Spare Part Catalouge?

Catalouges of replacement parts are more than just lists. A well-structured and exhaustive inventory of all the replaceable components, descriptions, and specifications for a system or equipment. Teams involved in maintenance, repair, and overhaul (MRO) production, Telescopic Handler automotive, aerospace, and consumer electronics rely on these Catalouges for daily tasks.

Catalouges aid in reducing expenses, downtime, and operational efficiency by delivering the correct components when needed. A spare component catalouge could come in handy in the following situations.

Maintenance and Repairs

Repairs and maintenance are a breeze when you have a well-organized catalouge of spare parts. Consider the Merlo brand of telehandlers. In the construction and agricultural industries, they are vital. Without a comprehensive catalouge, finding the specific replacement components needed for these machines may be difficult.

Locating the right component and getting it quickly makes it possible to keep these gadgets running as much as possible. During crucial operational periods, this component is critically necessary. For example, every second counts in the agricultural business when harvesting crops. Much capital can be frittered away if the process takes too long. At this crucial stage, the harvest's success or failure depends on how fast a Merlo telehandler can grab a particular area.

Save Money

Cost Savings

One way to save costs is to buy replacement components in advance from a catalouge. Spare part prices could go up or down depending on many factors, including fluctuations in supply and demand or shortages of essential raw materials.

Companies may save a ton of money if they buy replacement parts in bulk while the costs are low. Stocking up on key spare parts in advance instead of buying them as required might help businesses reduce maintenance expenses by 25% in 2023.

With this method, costs may be better managed, and operations can continue as usual, even when parts are out of commission. Businesses in the agricultural and construction industries that use Merlo telehandlers daily would greatly benefit from this method of stockpiling replacement components.

Equipment Longevity

Merlo telehandlers are essential in farming and construction. Therefore, keeping them in perfect condition is important so they last a long time. An important component of this is using parts made by the original equipment manufacturer (OEM) and making sure to stay up with maintenance. You may extend the life of your machine by 20% by replacing aftermarket components with OEM (original equipment manufacturer) ones.

A Merlo telehandler could cost anywhere from $80,000 to $120,000. No company could afford to skip out on such a major investment in equipment. Maximizing your investment and ensuring its dependability is best accomplished by providing a lengthy service life. For example, a telehandler's lifespan may be increased from 10 to 12 years by replacing aftermarket components with OEM (original equipment manufacturer) ones. During the equipment's lifespan, this 20% improvement in longevity may lead to significant cost savings and fewer downtime.

Although they may be more expensive, OEM (original equipment manufacturer) components are certain to fit your car perfectly and last far longer than aftermarket alternatives. Take the $1,000 price tag of an OEM hydraulic pump as an example, compared to the $700 price tag of an aftermarket pump. Nevertheless, the Merlo telehandler is engineered to work seamlessly with the OEM pump, preventing expensive failures.

Also, construction and agricultural companies can lose more money during peak seasons because of downtime than they would save by buying aftermarket parts. Durable and dependable components have been crucial since 2019. Research has found that companies might lose over $500 per hour because of equipment downtime.

Compliance and Safety

Always utilize the right, manufacturer-specified components when servicing equipment in the construction and agricultural sectors to preserve compliance and safety. Reliable and efficient machinery, such as Merlo telehandlers, is perfect for this task. You must use genuine Merlo parts to be safe and out of trouble with the authorities. By using these components, you can further guarantee that the equipment will operate at peak efficiency and adhere to all applicable safety standards.

In the United Kingdom, the Health and Safety Executive (HSE) is in charge of implementing strict regulations regarding the upkeep and security of equipment. Fines and other legal ramifications of several thousand pounds might result from noncompliance, especially when using incorrect or low-quality components. Some companies have paid penalties exceeding £100,000 in recent years for violations of safety standards related to equipment maintenance.

Telehandlers and other heavy equipment are vital in the agricultural and construction sectors. Using unspecified components increases the likelihood of failure, which increases the possibility of costly downtime and financial losses. Although spending extra on genuine components may seem wasteful, downtime for a single piece of equipment might surpass £1000 daily.

Be careful to adhere to the manufacturer-specified maintenance procedures and only use genuine Merlo components on your telehandler. Genuine Merlo components may range in price from a few hundred to a few thousand pounds. Gears and hydraulic pumps are essential components whose replacement parts are more expensive. Investment in this equipment is important to ensure security, optimal performance, and adherence to industry standards.

Inventory Management

Businesses, particularly those in the construction and agricultural industries, who use Merlo telehandlers for inventory management would greatly benefit from a complete catalouge of replacement parts. This method makes it much easier to determine which components are required for various models and when to perform maintenance. Because of this, businesses will never be short on replacement components. Understocking may cause equipment downtime, which might impact productivity; overstocking can cause cash to be wasted.

According to recent research by industry experts, one way to keep costs low is to have a good supply of replacement parts. An efficient inventory management system has helped some businesses cut their storage expenses by 15%. Merlo telehandlers are essential for lifting jobs on agricultural and construction sites, and streamlining the administration of replacement components for these machines may have a significant financial effect. For instance, if replacement parts are hard to come by and equipment goes down for no apparent reason, the resulting personnel expenses and missed productivity might amount to $3,000 daily.

The fact that Merlo telehandler parts may cost anywhere from $100 for little components to more than $5,000 for major ones, such as engines or gearboxes, proves that there is an economic justification for reducing inventory. The two primary benefits of effective inventory management are minimizing operational interruptions and decreasing holding costs associated with excess inventory.

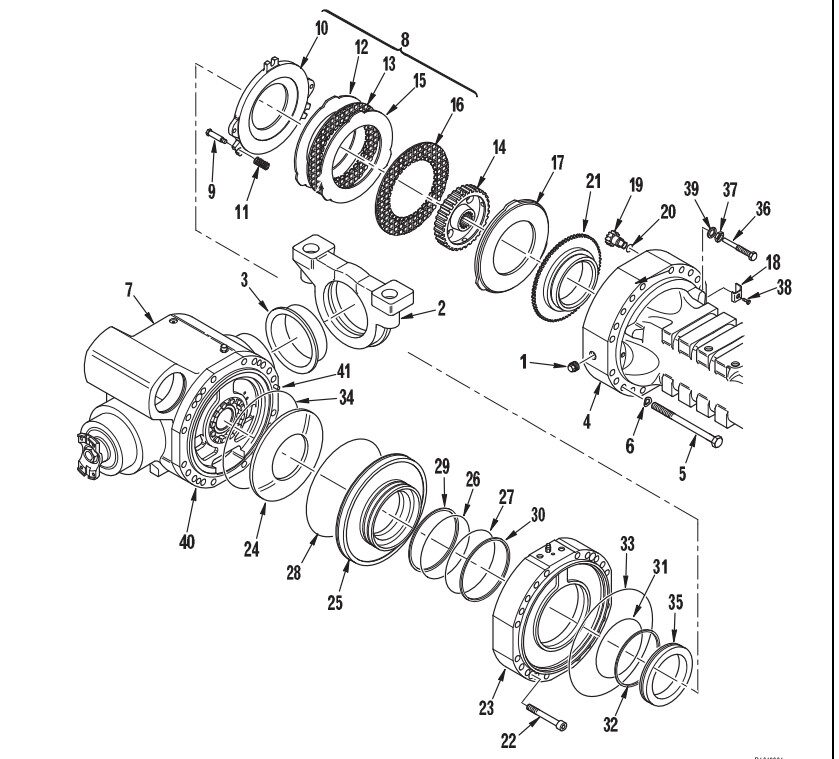

Nothing beats the crucial information found in Merlo manuals regarding maintaining your equipment. You may be certain that all your repair and maintenance requirements will be fulfilled with the help of clear and comprehensive diagrams and instructions. Because of their user-friendly design, these reliable instructions are fast and simple. Our manuals are easy to understand, and as a bonus, these manuals are printable!

No comments

Leave a reply

Cart

Cart is empty.